| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : YUHONG

Model Number : ASTM B407

Certification : ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008

Place of Origin : CHINA

MOQ : 1 PC

Price : 1-100000 USD

Payment Terms : T/T, L/C

Supply Ability : 1000 tons/month

Delivery Time : 5-65 days

Packaging Details : Ply-wooden Case / Iron Case / Bundle With Plastic Cap

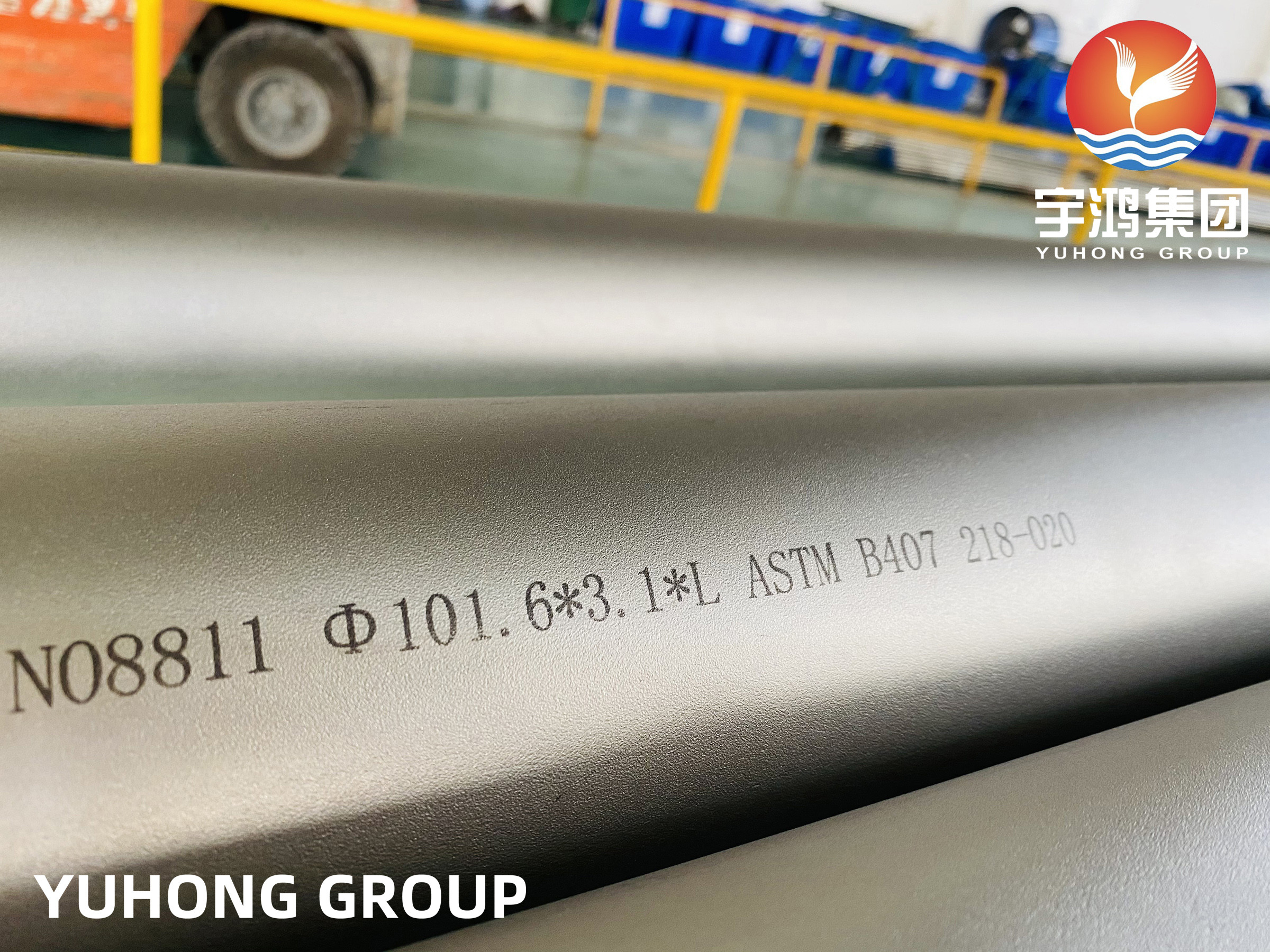

Product : Seamless Tube

Material : Nickel Alloy Steel

Standard : ASTM B407

Grade : UNS NO8811

Type : Round

Packing Details : Ply-wooden Case / Iron Case / Bundle With Plastic Cap

Third Party Inspection : BV, SGS, ASP

Length : Up to 6 Meters

ASTM B407 UNS NO8811 Nickel Alloy Seamless Tube For Petrochemical and Refinery

ASTM B407 UNS N08811 is a nickel-iron-chromium alloy tube designed for use in high-temperature and corrosive environments. It is commonly known as Alloy 800HT, which is a high-performance material offering excellent resistance to oxidation, carburization, and other forms of high-temperature corrosion. The seamless tube form ensures superior mechanical properties and structural integrity under demanding conditions.

Key Features of ASTM B407 UNS N08811 Seamless Tube:

High Temperature Resistance

Alloy N08811 exhibits excellent thermal stability, making it ideal for applications involving prolonged exposure to temperatures up to 1100°F (593°C) and higher.

Corrosion Resistance

The alloy provides exceptional resistance to oxidation, carburization, and sulfidation, even in extreme environments like chemical processing plants.

Mechanical Strength

Enhanced mechanical properties due to the addition of controlled levels of titanium (Ti) and aluminum (Al), ensuring excellent creep and stress rupture strength.

Seamless Construction

The seamless manufacturing process ensures uniformity, eliminates weak points, and provides superior strength and reliability compared to welded tubes.

Chemical Composition:

The typical chemical composition of UNS N08811 is as follows:

Applications:

Due to its outstanding properties, ASTM B407 UNS N08811 is widely used in industries such as:

Standards and Specifications:

Advantages of Using UNS N08811 Seamless Tubes:

|

|

ASTM B407 UNS N08811 Nickel Alloy Seamless Tube for Petrochemical Images |